Hello Brands & Businesses!

Custom Bottle Labels on Rolls for Organisations of All Shapes & Sizes

- E-Mail: info@primelabels.com.au

- Call: 1800 954 777

Luxury, hot foil labels

Hot foil stamping and hot foil labels can give your printed rolls a luxury feel. They’re often used in conjunction with premium materials on luxury food, beverage and cosmetic product labels.

We love these processes because they provide a real sense of quality and value for a reasonable price. (It also makes our artists proud when they create something really attractive.)

Note: It’s not the same as ‘embossing’. While they can be performed together (and to great effect), they are two completely independent processes.

Hot foil stamping (aka foil blocking)

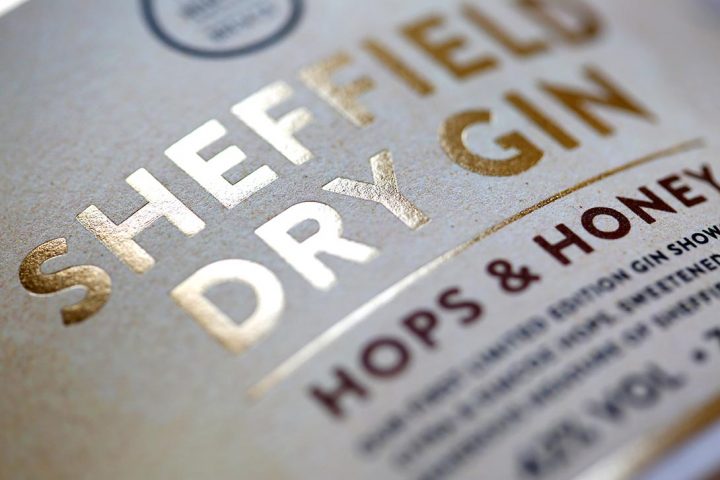

With hot foil stamping, a specially cut metal die is used to apply a thin film of foil in a specific pattern (or as text) to the label through heat and pressure. While the foil is typically gold or silver, it can be just about any colour-metallic and non-metallic.

Originally called ‘foil blocking’, the process has been around for centuries old. But that all changed in the 1930s, when they started producing extremely thin foil by laying it out on polyester rolls. Thanks to that discovery, the process is now much less expensive and labour intensive.

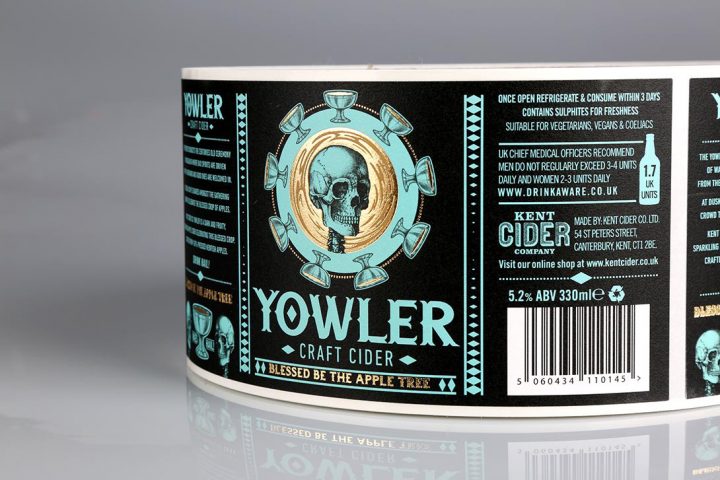

Most foil blocking is done using metallic foils. If you see any metallic colours on a product label, chances are they were created using hot stamped metallic foils. If you want you labels to look lustrous and shiny, this is the most effective method currently available.

Another option is to use pigmented foils—opaque (or semi-opaque) foils file in ‘chromatic’, non-metallic colours. These are often used to provide a dramatic contrast to the rest of the label. (Black and white are very popular colours.) While they don’t have the same visual flair as metallic foils, they still convey a sense of value and quality.

Hot foil stamping tips

Remember this is an inkless process, and that the label’s base colour won’t affect the foil. So applying it to a dark or even black label will make it really stand out.

You can create a variety of finishes with hot foil stamping by using gloss, matt, pearlescent, marbled or even 3D holographic foils.

The process for multi-colour foil printing involves running your labels through the press multiple times-once for each colour. For that reason your labels will be more expensive to produce.

Hot Foil FAQs

We recommend the minimum line thickness for any hot foil element should be 0.2mm. It’s always worth sending a copy of your proposed artwork file to the Customer Service team for a definitive answer; info@primelabels.com.au

Ensure that your label artwork files are print-ready; download our data delivery guide.

Tools & Resources

Use Our Online Calculator Tool and Calculate the Costs of Your Custom-Roll Labels in Real-Time.

In order to review and test our materials & print quality most comprehensively, we recommend requesting a complimentary Sample Pack.

Do you have specific questions regarding a current requirement or project?

Please feel free to leave us a message.

Alternatively;

- Tel: 1800 954 777

- E-Mail: info@primelabels.com.au

Questions? We’re

here to help!

Custom Labels Summary:

- Premium-Quality Materials

- Any Shape, Any Size Labels

- Industry & Machine Ready

- Custom Roll Sizes

primelabels.com.au Summary:

- Trusted Label Manufacturer

- Calculate & Order Online

- Free Delivery

- 5-10 Working Day Turnaround

Additional Useful Links: